Motion Platform (base)

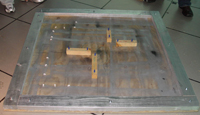

Rocker. The base is composed of a 35’’x35’’ rocker in an X form to rock in both directions Left/Right and Front/Back. The rocker is cut in the woodshop in UF in a way where it can be blocked by wooden blocks for safety while sitting in and going out. Two pieces of wood are bolted together to make it more stable.

Sliders.

On top of the Rocker three 24’’ x 24’’ squares

on top of each other where between the 1st and the second pieces

we have 3 parallel rails to slide from Left/ Right. Between the 2nd and

the 3rd

pieces we have another 3 parallel rails to slide Front/Back .

Sliders.

On top of the Rocker three 24’’ x 24’’ squares

on top of each other where between the 1st and the second pieces

we have 3 parallel rails to slide from Left/ Right. Between the 2nd and

the 3rd

pieces we have another 3 parallel rails to slide Front/Back .

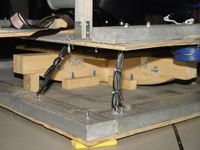

Rocker + Sliders.

The rocker and sliders are joint together by L-shaped metal

pieces with 4 each on each side of the rocker, so the total

of L shaped pieces is 8 with 4 screws each (total of 32 screws).

Rocker + Sliders.

The rocker and sliders are joint together by L-shaped metal

pieces with 4 each on each side of the rocker, so the total

of L shaped pieces is 8 with 4 screws each (total of 32 screws).

A 35’’x48’’ platform is mounted by 4 long and thick bolts, washers and hex-nuts in the center. The bolts attach the top wooden platform of the slider. This is the main platform where the chair is mounted and the user steps on this platform to get in.

Another perforated sheet is sprayed silver and is mounted on top of this platform just for the aesthetics. It is mounted by tens of non Philips screws that look hexagonal. Mainly used for the aesthetics.

Motion Constraint. The

rocker rotates along the Z axis and we don’t want this effect.

Another 48’’x48’’ platform is put on the floor

under what we built so far and 4 wooden blocks are added to

this platform so the rocker fits in to stop the rotation.

Motion Constraint. The

rocker rotates along the Z axis and we don’t want this effect.

Another 48’’x48’’ platform is put on the floor

under what we built so far and 4 wooden blocks are added to

this platform so the rocker fits in to stop the rotation.

We also noticed that the motion range is too big for our needs,

so we attached 4 hooks on the corner of the main platform and

another 4 hooks are attached to the corners of the bottom platform

too. 4 super strong sports rubber bands go through the top and

bottom hooks of each corner attaching the top and bottom platforms

together on the 4 corners.

This works but now the load is still on the center and the rubber bands

are pulling from 4 corner in the 4 directions, so the bottom platform started

buckling and the rotation problem is back. Worried of the safety, we bought

4 strong 48’’ wooden pieces and attached those to the edges

of the bottom platform. Now it’s stable but a little rotation is

still there, to fix this we put some high friction rubber material between

the floor and this platform …. And problem solved !!

This works but now the load is still on the center and the rubber bands

are pulling from 4 corner in the 4 directions, so the bottom platform started

buckling and the rotation problem is back. Worried of the safety, we bought

4 strong 48’’ wooden pieces and attached those to the edges

of the bottom platform. Now it’s stable but a little rotation is

still there, to fix this we put some high friction rubber material between

the floor and this platform …. And problem solved !!

Chair

The chair is mounted on top of the 35x48 platform by 4 long

screws on the rail that come built-in the chair.

The chair is mounted on top of the 35x48 platform by 4 long

screws on the rail that come built-in the chair.

Shakers

We are using two source of vibration, the first is the built-in

NAVE vibrators under ground. Since the physical platform

is made of many layers, the vibration signal arrives weak so we added 2

more shakers, one

on each side, under the 35x48 platform. They are hooked up

with 4 screws each.

We are using two source of vibration, the first is the built-in

NAVE vibrators under ground. Since the physical platform

is made of many layers, the vibration signal arrives weak so we added 2

more shakers, one

on each side, under the 35x48 platform. They are hooked up

with 4 screws each.

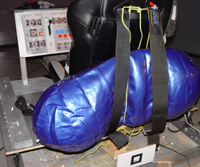

Harness

A five point harness is used to strap the user in the chair and to feel

the pressure of the launch later on. The harness is screwed

to the main platform so each end of the 5 straps is fixed on one side.

A strong sports

balloon is inserted between the two back straps and the chair,

this balloon is inflated using an inflator later so the user feels the

pressure on the

chest. A neck pillow is put between the harness and the user’s

neck so when the harness is tightened, he will still feel the pressure

without

hurting his neck.

A five point harness is used to strap the user in the chair and to feel

the pressure of the launch later on. The harness is screwed

to the main platform so each end of the 5 straps is fixed on one side.

A strong sports

balloon is inserted between the two back straps and the chair,

this balloon is inflated using an inflator later so the user feels the

pressure on the

chest. A neck pillow is put between the harness and the user’s

neck so when the harness is tightened, he will still feel the pressure

without

hurting his neck.

Interaction: Keyboard + Joystick

The user is asked to press 7 buttons in a row to check the controls. These

buttons are NOT regular keyboard buttons. The front panel consists

of a wooden frame attached to the main platform. On the horizontal

part of the

frame two hinges attach the platform to the wooden base that

supports the keyboard. Now the base rotates about the frame

to make the panel slanted

and movable so the user can get in the chairs without the need

of too much space. On top of the keyboard base sits the actual

keyboard and on top

of the keyboard there is another wooden plate that looks from

the outside like the cockpit that the user sees on the screen.

The user is asked to press 7 buttons in a row to check the controls. These

buttons are NOT regular keyboard buttons. The front panel consists

of a wooden frame attached to the main platform. On the horizontal

part of the

frame two hinges attach the platform to the wooden base that

supports the keyboard. Now the base rotates about the frame

to make the panel slanted

and movable so the user can get in the chairs without the need

of too much space. On top of the keyboard base sits the actual

keyboard and on top

of the keyboard there is another wooden plate that looks from

the outside like the cockpit that the user sees on the screen.

A

texture is printed and pasted on the wood. The top and bottom

plates are perforated

and bolted with 4 bolts and the keyboard is between both plates.

The top plate is

drilled and 7 actual buttons touch the keyboard using a retractable

pen mechanism. Actual pens were cleaned and inserted through

the holes to touch

the keys from the keyboard side and a spring on the other side

make the pen release the button after it’s pressed. The top aesthetics

of the button are red circular and blue square wooden pieces

glues on the pens with a plastic glue gun.

A

texture is printed and pasted on the wood. The top and bottom

plates are perforated

and bolted with 4 bolts and the keyboard is between both plates.

The top plate is

drilled and 7 actual buttons touch the keyboard using a retractable

pen mechanism. Actual pens were cleaned and inserted through

the holes to touch

the keys from the keyboard side and a spring on the other side

make the pen release the button after it’s pressed. The top aesthetics

of the button are red circular and blue square wooden pieces

glues on the pens with a plastic glue gun.

Thejoystick is another

mean of interaction used when docking to the space station.

It is mounted on its own black painted box.

Thejoystick is another

mean of interaction used when docking to the space station.

It is mounted on its own black painted box.

Tracking marker

A marker is attached to the base that rocks and is tracked

optically by a web-cam.

the marker is not attached directly on the platform because

it gets out of the camra’s field of view, so a wooden piece extends

from the rocker outward so the marker is attached to it without being blocked

for certain positions.

Safety factors

Safety is out priority number one, so whenever 2 screws are enough we were putting 5 to be really solid and support different body weights and motions. Whenever 2 small rails are enough, we put 3 big one. Wooden blocks are used to lock the rocker when the user gets in.

Aesthetics

All the wooden blocks are sprayed silver before attaching them. All non functional buttons are sprayed black and all functional one are painted blue or red using acrylic paint. A perforated board is sprayed and attached just for the aesthetics of it so it looks like metal.

Comfort & Feeling

The racing chair is used to have the same sitting feeling. A pillow is used under the harness so the tightened harness does NOT hurt the user’s neck A foot rest is attached in the front so tall users can sit there comfortably. And guess what, this piece is made out of the complementary parts cut out of the rocker.

3D Models & Video

All the models including the cabin, space shuttle, space station, solar

system and asteroids were created realistically using 3D Studio Max and

based on photos of the originals. The models are exported into Open Flight

format and later imported into Vega Prime. The briefing video also involved

an animation created in 3D Studio max. The editing of the briefing video

was done with Adobe Premiere. Cool Edit was used for editing sound clips.

All the models including the cabin, space shuttle, space station, solar

system and asteroids were created realistically using 3D Studio Max and

based on photos of the originals. The models are exported into Open Flight

format and later imported into Vega Prime. The briefing video also involved

an animation created in 3D Studio max. The editing of the briefing video

was done with Adobe Premiere. Cool Edit was used for editing sound clips.